BOM Conversion

Pre-assembly Verification

Component Engineering

Assembly tool

Why use PCB Planet’s engineering support services?

- More competition means more RFQs. If you don’t get the order you have wasted valuable engineering resources.

- PCB Planet has a pool of experienced engineers available 24X7X52 so your own engineers can concentrate on higher added-value tasks.

- Tighter margins mean costings must be more precise but your customers demand faster quotations.

- PCB Planet can provide a full BOM analysis and verification service. We can interface with your preferred component suppliers to provide the pricing information you need for a precise quotation.

- Tight margins and fast deliveries mean that production issues must be sorted upfront.

- PCB Planet’s component verification service checks every aspect of the manufacturability of the design. You get no surprises at the production stage. Fast feedback to your customers enhances your supplier profile.

- Shorter production runs mean more tooling for assembly equipment.

- PCB Planet’s engineers work closely with your in-house production staff to deliver verified tooling for pick and place and printing machines to your precise specification.

PCB Planet’s engineering support services bring wider enterprise benefits:

- More reliable deliveries.

- When demand peaks threaten delivery schedules PCB Planet’s support services deliver extra capacity as you need it. Our services are available 24X7X52.

- Lower costs.

- PCB Planet’s offshore operation and economies of scale can reduce your data preparation costs. Reduce capital investment and operating, training and management costs to free resources for other areas of business growth.

- Enhanced enterprise skills base.

- Offloading low added-value tasks to PCB Planet allows you to refocus your in-house knowledge base onto your core competencies.

- Reduced enterprise risk.

- PCB Planet outsourcing eliminates the risk of lost capacity due to sickness, holidays or the loss of key staff

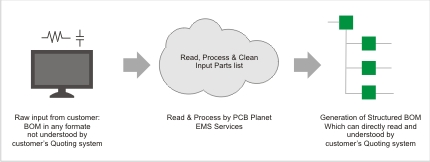

BOM Conversion

Has your customer supplied his BOM in a format you can’t read directly into your costing system?

PCB Planet’s engineers will

- Input BOM in any format

- Verify it against the PCB data

- Output in your preferred format

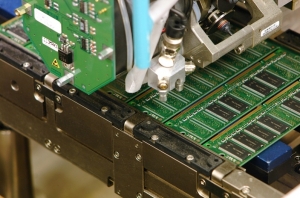

Pre-Assembly Verification

Detect potential problems before production starts by comparing the BOM with the CAM fabrication data.

The service typically includes:

- Comparing PCB footprint against the component package to avoid placement error

- Reporting missing, duplicate components

- Catch packages inconsistency before actual assembly

- Verification of component spacing to avoid poor soldering or difficulty in rework

- Detecting possible solder shorts

- Solder paste verification to avoid missing or extra solder paste on SMD /Test point, missing mask opening error, misalignment on copper feature

- Fiducial verification to avoid Machine vision detection error

Component Engineering

Need to program more shorter runs on fast turnarounds? PCB Planet engineers are available 24 X7 X 52 for:

The service typically includes:

- Part Cross

- RoHS Compliance Scrub

- Process Max Temperature Scrub

- Obsolescence Scrub

- Component procurement assistance

Assembly Tool Preparation

Need to program shorter runs on fast turnarounds? PCB Planet engineers are available 24 X7 X 52 for:

- Stencil data preparation

- Machine programming for pick & place and inspection systems

- Data output to your rules and in your preferred formats

- Feeder loading list in excel or ascii format

- Assembly drawing